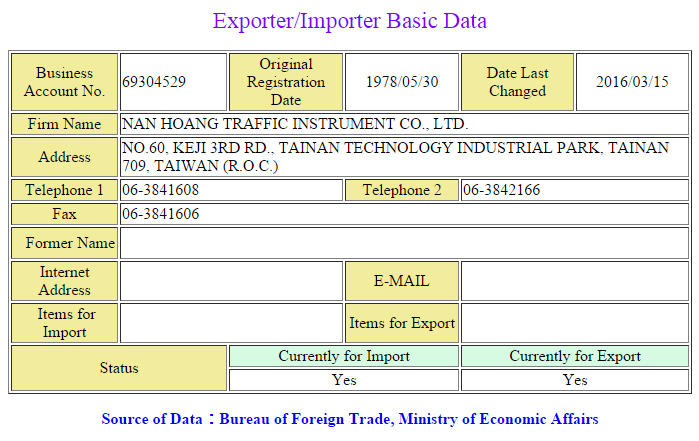

NAN HOANG TRAFFIC INSTRUMENT CO., LTD. 南晃交通器材工業股份有限公司

Company Information

| Company Name: | NAN HOANG TRAFFIC INSTRUMENT CO., LTD. 南晃交通器材工業股份有限公司 |

|---|---|

| Business Type: |

|

| Factory Type: |

|

| Establish: | 1961 |

| Website: | http://www.nhc-brakes.com/ |

| Location: | Taiwan |

| Export Registration: |

|

| Main Products: |

Drum Brake Shoes Disc Brake Pad |

| Member of Associations / Guilds: | Taiwan Transportation Vehicle Manufacturers Association |

| Position: |

Brake pad for cars, special type of vehicle with E-Mark, professional and amateur racing cars and Go-karts. All the raw materials contain no toxicity that conform with the international environmental protection. Accept to make orders for special products, for the diameter up to 1200mm and 900mm length in square.

|

| History: |

San Hoang established, starts manufacturing Friction Materials. Wu-Jen Cheng, the founder of San Hoang began with 3000 NT and with this, began to produce motorcycle brake pads. 1963 Name changed to “Nan Hoang Resin Industrial Co., LTD.” 1965 Successfully develop agricultural clutch plates; supplying “Kutoba Japan” OE manufacturer begins. 1970 Nan Hoang Resin Industrial Co., LTD. manufacturing range is increased as fabrication of boat clutches and brake lining starts. 1975 Name changed to “Nan Hoang Traffic Instrument Co., LTD.”, Nan Hoang institutes new quality control measures; first year of mass production. 1982 Successfully develop sintered bronze brake pads and clutches. 1985 Railway brake pads and linings are added to the range of products Nan Hoang manufactures. 1990 Newly refined Go Kart brake pads developed. 1994 Established “Song Fei Tai Industrial Co., LTD.” as a subsidiary company, Song Fei Tai produces industrial machined friction materials, asbestos free friction materials also developed. 1995 Successfully develop paper type clutch plates. 1996 Completed Qualification for OE standard automatic batching and mixing system, obtained ISO 9002 international quality system certification. 1997 Certified QS 9000 international quality system acquired, Krauss performance tester and inspection equipment are now used. Nan Hoang becomes the largest friction material manufacturer in Taiwan; non-asbestos bicycle brake pads developed. 1998 The mass production of asbestos free NAO automotive brake pads start, supplying forklift OE manufacturers begins. 2000 Nan Hoang complies with OE manufacturer quality control system; obtained ISO14001 environment management system certification; established the biggest friction material laboratory in Taiwan; enhanced the multi-functional testing equipment to provide the physical and performance analysis service. 2002 Successfully develop ceramic NAO disc brake pads; received ABE/ECE R90 E1 quality certification for automotive disc brake pads. 2003 Obtained ISO/TS 16949 international quality system certification; technical exchange with international friction researchers and technicians. 2004 Ceramic NAO disc brake pads sales to North American Region increase. 2005 Friction research and development center established, focus towered eco-friendly products, entrance into motorcycle OE manufactureing. 2006 “Taiwan First Brake Technology Co., LTD.” established for OE manufacturers. Successfully develop racing asbestos free disc brake pads. 2007 NHC moves to more modern manufacturing factory with greater capacity, granted “TUV” quality certification for bicycle brake pads. 2008 Successfully develop CVT clutch weight for motorcycle OE market. 2009 Obtained ECE R78/ABE quality certification for motorcycle brake pads, granted TOSHMS (Taiwan Occupational Safety and Health Management System) certification. 2010 Successfully develop the wind generator disc brake pads. Introduce the electronic microscope element analyzer, enhance friction material R&D capabilities. 2011 Successfully sell ceramic NAO disc brakes to electronic car manufacturers in North America. 2012 Complete low copper, copper free and green disc brake pads, Sponsor brake pads to Taiwan International Racing Circuit and sponsored vehicle wins championship. 2013 - 2015 Expands the new facility, introduce the new automatic disc brake pads production line and precise equipment. |

| Business Philosophy: |

Keeping in step with new technological advances, braking performance and the stability of the friction material are required to be greater. Not resting on our accomplishments, in the days and years ahead, we will team up with even more scientific and academic authorities to develop new products with additional benefits and in line with the newest advancing technology. Meanwhile, Nan Hoang will continue to be extremely motivated to carry out the systems of TS16949 & ISO 14001 to the best ability. In the coming future, Nan Hoang will systematically expand its markets, develop new technology, improve upon previous designs and strive toward a promising future amidst mounting competition in the international community. |

| Quality Guarantee: |

“We provide drivers the best security, the excellent performance, and the comfortability.” With Nan Hoang’s R&D ability, products, and service, we can promote your driving safeness and comfort. We believe that we are able to reach a long-lasting satisfaction from our customers through our brake pads.

“We reassure your driving safeness by our products.” By high-performance, good quality, owned formula, and wonderful service, we guarantee your experience on the most quiet, noise-free, and dust-free driving status. “We are the experts in the field Eco-friendly brake pads.” Our products are qualified by Europe’s ROHS, REACH environmental regulations and R90 certification. We insist on 100% non-asbestos formula, and 100% made in Taiwan.

|

| Environmental Policy: |

Global warming is a serious topic that is commonly discussed by individuals and corporations through the world. Different type of pollutions, water, air, noise, and heavy metal cause harm to both the atmospheric and environmental conditions and ecologies. As a friction material manufacturer in Taiwan for 55 years, Nan Hoang and its associate, would like to participate in providing greener products for consumers and help society as a whole. In January 2012, Nan Hoang started to develop the low copper and copper free disc brake pads, Nan Hoang would like to be even more innovative in the future as well as see larger consumption of these more ecological materials. In June 2012, these eco-friendly pads were finished and they are rated in initial performance, wear life, rotor offensive, fading, climate temperature efficiency, high temperature resistance, high speed efficiency (180 km/h), noise, and dust to create and even higher standard of performance.

|